sel 351s instruction manual

The SEL-351S Protection System offers real-time system state measurement with IEEE C37.118 synchrophasors, providing wide-area stability awareness and built-in Ethernet for simplified communications. It features a 10-year warranty and user-friendly controls.

Product Overview

The SEL-351S Protection System is a advanced relay designed for wide-area system stability awareness and real-time measurement. It provides time-synchronized voltages and currents in the IEEE C37.118 standard format, enabling precise system monitoring. With built-in Ethernet connectivity, the SEL-351S simplifies communication and integration into modern power systems. The relay features large, easy-to-use operator controls and optional independent SafeLock trip/close pushbuttons, enhancing operational safety and simplicity. It supports synchrophasor measurements, load oscillation detection, and voltage profile analysis, making it a versatile tool for power system protection and control. The SEL-351S is backed by a standard 10-year warranty and is supported by comprehensive documentation, including user manuals and software tools. Its robust design and advanced features make it ideal for applications requiring high accuracy and reliability in power system protection and monitoring.

Key Features of the SEL-351S

The SEL-351S Protection System boasts several advanced features, including real-time system state measurement with IEEE C37.118 synchrophasors for wide-area stability awareness. It offers built-in Ethernet connectivity for seamless communication and integration into power systems. The relay includes large, easy-to-use operator controls and optional independent SafeLock trip/close pushbuttons, enhancing operational safety and simplicity. Additional features include time-synchronized voltages and currents, load oscillation detection, and voltage profile analysis. The SEL-351S supports synchrophasor measurements, enabling precise monitoring and control of power systems. It also features a robust design with a 10-year warranty, ensuring long-term reliability. These features make the SEL-351S an ideal solution for applications requiring high accuracy, advanced protection, and simplified operation in modern power systems.

Technical Specifications

The SEL-351S Protection System is designed to meet the IEEE C37;118 standard for synchrophasor measurements, ensuring high accuracy and reliability. It features built-in Ethernet connectivity for efficient communication and integration into modern power systems. The relay supports time-synchronized voltages and currents, enabling precise monitoring and control. With optional independent SafeLock trip/close pushbuttons, the SEL-351S enhances operational safety and simplicity. The device is backed by a standard 10-year warranty, underscoring its durability and performance. Technical specifications include advanced synchrophasor capabilities, load oscillation detection, and voltage profile analysis, making it suitable for wide-area system stability applications. The SEL-351S is engineered to provide robust protection, metering, and control functions in demanding power system environments.

Installation and Configuration

Pre-installation requirements include proper site preparation and compliance with safety standards. Installation steps involve mounting, wiring, and configuring the SEL-351S according to the manual. Configuration options ensure tailored functionality.

Pre-Installation Requirements

Before installing the SEL-351S, ensure the site meets all safety standards and guidelines. Handle the device with care to avoid damage from electrostatic discharge. Review the English language manual thoroughly for specific instructions. Ensure all necessary tools and materials are available. Verify compatibility with existing systems and prepare the mounting location according to specifications. Familiarize yourself with the product’s features, such as Hot Line Tag and Synchronism Check, to ensure proper setup. Adhere to all warnings and cautions provided in the manual to prevent unauthorized access and potential damage. Proper preparation ensures a smooth and safe installation process.

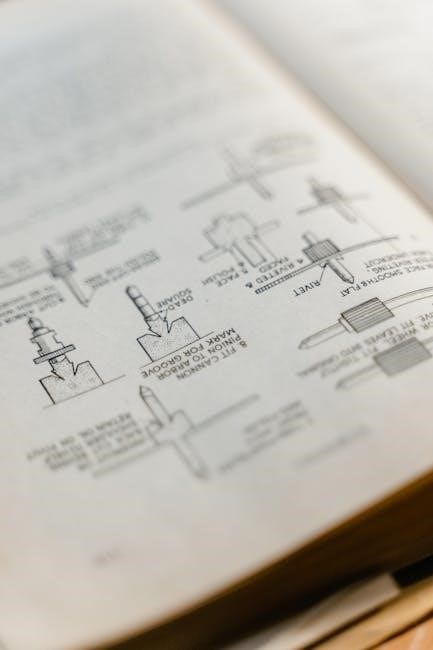

Installation Steps

Mount the SEL-351S in a secure, ventilated area, ensuring proper grounding and compliance with safety standards. Connect the current and voltage transformers to the designated terminals, following the manual’s wiring diagram. Power up the device and verify the front-panel interface initializes correctly. Configure the communication ports as needed, such as Ethernet, for remote access and data transmission. Test all inputs and outputs to ensure proper functionality. Use the provided screws to secure any external connections firmly. Finally, perform a system test to confirm accurate measurements and operation. Refer to the manual for specific torque and wiring specifications to avoid damage or malfunctions.

Configuration Options

The SEL-351S offers flexible configuration options to meet specific system requirements. Users can customize settings such as communication protocols, data formats, and security features through the front-panel interface or external software tools. The relay supports IEEE C37.118 synchrophasor settings, allowing precise synchronization and data transmission. Configuration of protection elements, such as fault detection thresholds and trip settings, can be tailored to suit various applications. Additionally, the SEL-5078-2 synchroWAVe software enables advanced configuration and analysis of system parameters. Security features, including password protection and access control, can be set up to ensure system integrity. The device also allows customization of display settings and alarm notifications for enhanced operational convenience. These configuration options ensure the SEL-351S can be adapted to a wide range of power system monitoring and protection scenarios.

Operating the SEL-351S

The SEL-351S operates with real-time system state measurement, utilizing IEEE C37.118 synchrophasors for precise data capture. Built-in Ethernet simplifies communication, and user-friendly controls enhance operational efficiency and monitoring capabilities.

Front-Panel Interface

The SEL-351S features an intuitive front-panel interface designed for ease of operation. Large, easy-to-use controls provide quick access to essential functions, while optional independent SafeLock trip/close pushbuttons enhance operational safety and simplicity. The interface includes indicators for system status and fault detection, ensuring clear visibility of relay operations. The front panel also supports synchronization checks and hot line tagging, though these features do not supervise the auxiliary close pushbutton. For sensitive applications, the SEL-351S offers a dedicated channel IN rated at 0.05 A nominal for precise measurements. The interface is complemented by a user-friendly layout, making it accessible for both routine operations and advanced configurations. Proper handling is essential, as the relay contains static-sensitive components that require precautions during installation and maintenance.

Basic Operating Procedures

Operating the SEL-351S begins with powering on the device and initializing its settings. Ensure all connections are secure and properly configured. The relay provides real-time system state measurements, including voltages and currents, in the IEEE C37.118 standard format. Use the front-panel controls to navigate through menus and access basic functions. Monitor system stability and phase angles using synchrophasors, which enable wide-area awareness. Perform routine checks on fault detection and load oscillation monitoring. The built-in Ethernet simplifies communication for data analysis. Always refer to the instruction manual for specific procedures, such as enabling Hot Line Tag or Synchronism Check features. The SEL-351S is designed for ease of use, with intuitive controls and clear status indicators. Regularly review system data to ensure optimal performance and compliance with safety standards. The device is backed by a 10-year warranty, ensuring long-term reliability and support.

Advanced Operating Features

The SEL-351S offers advanced features for enhanced system monitoring and control. The Hot Line Tag feature ensures safe and efficient operation during live-line work, while the Synchronism Check prevents unintended closing of circuit breakers. These features are not supervised by the auxiliary close pushbutton, requiring careful operation. The relay supports synchrophasor measurements, enabling advanced analysis of system stability and phase angles. Users can integrate the SEL-5078-2 synchroWAVe software for centralized visualization and analysis of voltage profiles and load oscillations. Additionally, the device allows for customizable settings and advanced fault detection algorithms. The built-in Ethernet connectivity facilitates real-time data transmission and integration with third-party software for comprehensive system management. These advanced features make the SEL-351S a robust solution for complex power system applications, ensuring high reliability and precision in operation. Regular updates and technical support from SEL further enhance the device’s capabilities and user experience.

Communication and Connectivity

The SEL-351S features built-in Ethernet for seamless communication, supporting IEEE C37.118 synchrophasors and integration with third-party software for enhanced real-time monitoring and system stability analysis.

Communication Interfaces

The SEL-351S offers robust communication interfaces, including built-in Ethernet for high-speed data transmission. It supports IEEE C37.118 synchrophasor standards, enabling precise time-synchronized measurements. The device is compatible with SEL-5078-2 synchroWAVe software and third-party tools for advanced data analysis. Ethernet connectivity ensures seamless integration into existing networks, facilitating real-time monitoring and control. The relay also supports communication protocols that enhance system stability awareness and simplify data management. These interfaces allow for efficient exchange of system state information, including voltages, currents, and phase angles, making it ideal for wide-area monitoring applications. The built-in communication capabilities ensure reliable and secure data transmission, critical for maintaining system integrity and performance.

Network Configuration

The SEL-351S supports advanced network configuration options, enabling seamless integration into industrial networks. It features built-in Ethernet connectivity, allowing for high-speed communication and data exchange. The device is designed to operate with standard network protocols, ensuring compatibility with existing infrastructure. Network settings can be configured to meet specific requirements, including IP addressing, subnet masks, and gateway configurations. The relay also supports secure communication protocols to protect data integrity and prevent unauthorized access. With its robust network capabilities, the SEL-351S can be easily incorporated into wide-area monitoring systems, enabling real-time data transmission and analysis. The device’s network configuration options are user-friendly, allowing for efficient setup and management. This ensures reliable performance and secure data transmission in various industrial applications.

Data Management and Analysis

The SEL-351S enables advanced data management and analysis through its integration with the SEL-5078-2 synchroWAVe Central Visualization and Analysis Software. This software allows users to view and analyze system phase angles, load oscillations, and voltage profiles in real-time. The device provides time-synchronized voltages and currents in the IEEE C37.118 standard format, ensuring precise data accuracy. Users can also utilize third-party software for further analysis, enhancing flexibility in data interpretation. The SEL-351S supports wide-area system stability awareness, making it ideal for monitoring and analyzing large-scale power systems. Its data management capabilities enable efficient storage and retrieval of system measurements, facilitating detailed analysis and reporting. This feature-rich system simplifies the process of identifying trends, detecting anomalies, and optimizing system performance, making it a powerful tool for grid stability and reliability.

Safety and Compliance

The SEL-351S requires adherence to safety guidelines, including handling precautions for static-sensitive components. It warns against unauthorized access and notes that auxiliary close pushbuttons are not supervised. Compliance with industry standards is ensured.

Safety Precautions

Handling the SEL-351S requires care to avoid damage from electrostatic discharge, as it contains static-sensitive components. Users must avoid unauthorized access, as features like Hot Line Tag and Synchronism Check do not supervise auxiliary close pushbuttons. The relay warns against improper handling and emphasizes compliance with safety standards. Proper grounding and insulation are essential during installation. Personnel should follow industry safety practices when working with electrical equipment. The manual stresses that Schweitzer Engineering Laboratories is not liable for damage from misuse. Always refer to the official documentation for detailed safety guidelines to ensure safe operation and maintenance of the SEL-351S Protection System.

Compliance Standards

The SEL-351S Protection System adheres to the IEEE C37.118 standard for synchrophasor measurements, ensuring accurate and reliable data for wide-area system stability. It complies with industry regulations and safety norms, meeting the requirements for electrical and electronic equipment. The device is designed to operate within specified environmental conditions, maintaining performance and durability. Compliance with these standards ensures interoperability with other systems and tools, such as the SEL-5078-2 synchroWAVe software. The SEL-351S is certified to meet rigorous testing criteria, guaranteeing its suitability for various applications. By following these standards, the SEL-351S provides a robust solution for power system monitoring and protection, aligning with global technical specifications and user expectations for quality and reliability.

Handling and Storage Guidelines

Handle the SEL-351S with care to avoid damage. Use anti-static devices when touching internal components, as they are sensitive to electrostatic discharge. Store the device in a dry, cool environment, away from direct sunlight and moisture. The recommended storage temperature is between -40°C and 70°C, with humidity levels below 80%. Avoid exposing the relay to physical shocks or vibrations. When transporting, ensure the device is securely packaged in its original casing or equivalent protection. Before installation, inspect for any visible damage or tampering. Follow proper grounding procedures to prevent electrical hazards. Keep the SEL-351S away from conductive materials during storage to avoid unintended electrical connections. Regularly clean the device to prevent dust accumulation, which could affect performance. Always refer to the manual for specific handling and storage instructions to maintain warranty validity and ensure optimal functionality.

Maintenance and Troubleshooting

Perform routine maintenance by cleaning the device and checking connections; Use diagnostic tools to identify issues like error messages or faulty sensors. Address common problems promptly to ensure reliability.

Routine Maintenance

Regular maintenance is essential to ensure the SEL-351S operates efficiently. Clean the device periodically to remove dust and debris, which can affect performance. Check all connections and cables for integrity and tightness. Update the firmware and software to the latest versions for optimal functionality. Inspect the front-panel controls and buttons for proper operation. Verify that the Ethernet connection is secure and functioning correctly. Review the system logs to identify any potential issues before they escalate. Perform these tasks as part of a scheduled maintenance plan to maintain reliability and accuracy. Always refer to the official manual for detailed procedures and guidelines. Proper maintenance ensures the SEL-351S continues to provide accurate measurements and reliable protection. Regular checks also help prevent unexpected downtime and ensure compliance with safety standards.

Troubleshooting Common Issues

When troubleshooting the SEL-351S, start by consulting the instruction manual for specific guidance. Common issues include synchrophasor measurement errors, communication failures, and front-panel malfunctions. For synchrophasor inaccuracies, verify IEEE C37.118 settings and ensure proper time synchronization. Communication issues may require checking Ethernet connections or updating network configurations. If the front panel is unresponsive, restart the device or inspect for dust or debris. For relay-specific problems, ensure auxiliary close pushbuttons are functioning correctly, as features like Hot Line Tag and Synchronism Check do not supervise these buttons. Always handle the device with anti-static precautions to avoid damaging sensitive components. Use diagnostic tools provided in the software or refer to the manual for detailed troubleshooting steps. If issues persist, contact SEL technical support for assistance. Regular maintenance and updates can help prevent many common problems.

Diagnostic Tools and Techniques

The SEL-351S Protection System provides advanced diagnostic tools to identify and resolve issues efficiently. The SEL-5078-2 synchroWAVe software allows visualization and analysis of system data, including phase angles and voltage profiles, aiding in troubleshooting. The front-panel interface offers real-time monitoring of device status and measurements. Built-in diagnostic features include event logs and self-test functions to detect hardware or software malfunctions. For communication issues, verify Ethernet connections and network configurations. Use third-party software compatible with IEEE C37.118 standards for additional analysis. Regularly update firmware to ensure optimal performance. Always refer to the instruction manual for detailed diagnostic procedures. If issues persist, contact SEL technical support for further assistance. Proper handling and anti-static precautions are essential when performing hardware diagnostics to prevent damage to sensitive components.

Warranty and Support

The SEL-351S is covered by a standard 10-year warranty. For detailed warranty information, visit www.selinc.com or contact SEL customer service for assistance.

Warranty Information

The SEL-351S Protection System is covered by a standard 10-year warranty, ensuring long-term reliability and support. For detailed warranty information, users can visit the official SEL website at www.selinc.com or contact SEL’s customer service directly. This warranty underscores SEL’s commitment to product quality and customer satisfaction. Additionally, Schweitzer Engineering Laboratories, Inc. has approved only the English language manual for this product, ensuring clarity and consistency in technical documentation.

Technical Support Options

SEL offers comprehensive technical support for the SEL-351S Protection System, ensuring users receive assistance whenever needed. Support options include direct contact with SEL’s customer service team, accessible through their official website or via email. Additionally, the SEL website provides a wealth of resources, including user manuals, software updates, and troubleshooting guides, to help users resolve issues independently. For more complex challenges, SEL’s experienced technical support team is available to provide expert guidance and solutions. This robust support system ensures minimal downtime and optimal performance of the SEL-351S, catering to both routine inquiries and critical operational needs.

Documentation and Resources

The SEL-351S Protection System is supported by extensive documentation and resources to ensure optimal use and troubleshooting. The official SEL website provides access to user manuals, instruction guides, and software tools like the SEL-5078-2 synchroWAVe Central Visualization and Analysis Software. These resources are designed to help users understand and utilize the full capabilities of the SEL-351S. Additionally, the product is covered by a standard SEL 10-year warranty, with details available on the SEL website. Manuals and guides are available for free PDF download, offering detailed information on installation, configuration, and operation. These resources empower users to maintain and troubleshoot the system effectively, ensuring peak performance and reliability.

Additional Resources

The SEL-351S Protection System is supported by user manuals, guides, and software tools available on the SEL website. Training and certification programs enhance user expertise.

User Manuals and Guides

The SEL-351S Protection System is accompanied by comprehensive user manuals and guides, available for free PDF download. These resources include the Instruction Manual, which provides detailed information on installation, configuration, and operation. The manual covers essential topics such as front-panel interface, command summaries, and troubleshooting. Additional guides offer insights into advanced features like synchrophasor measurements and network configuration. The Instruction Manual also includes sections on safety precautions, compliance standards, and maintenance procedures. Users can access these documents on the official SEL website or through authorized distributors. The manuals are regularly updated, with versions like the Date Code 20001006 and Date Code 20230831 available for download. These resources ensure users can maximize the functionality and performance of the SEL-351S while adhering to safety and operational best practices.

Software Tools and Updates

The SEL-351S Protection System is supported by advanced software tools, including the SEL-5078-2 synchroWAVe Central Visualization and Analysis Software. This tool enables users to view and analyze system phase angles, load oscillations, and voltage profiles in real-time. Additionally, third-party software compatibility allows for flexible data management and analysis. Regular software updates are released to enhance functionality, improve performance, and address potential issues. Users can access these updates through the official SEL website or authorized distributors. The software tools are designed to integrate seamlessly with the SEL-351S, ensuring optimal system operation and compliance with industry standards. By leveraging these tools, users can maximize the capabilities of the SEL-351S while maintaining system stability and reliability. Updates are typically accompanied by release notes, providing detailed information on new features, improvements, and installation instructions.

Training and Certification

Training and certification programs for the SEL-351S Protection System are designed to enhance user proficiency and ensure optimal system operation. These programs cover theoretical and practical aspects, including installation, configuration, and troubleshooting. Participants learn to interpret data, analyze system performance, and utilize advanced features effectively. Certification is offered through authorized SEL training centers, verifying expertise in operating and maintaining the SEL-351S. Online courses and workshops are also available, providing flexible learning opportunities. These resources empower users to maximize the system’s capabilities while adhering to industry standards. By completing these programs, users gain the skills and knowledge needed to handle complex scenarios confidently, ensuring reliable and efficient system performance. Certification also demonstrates a commitment to professional development and compliance with best practices in power system protection and control.